CASOKU is a lubricant brand produced by EUROILTEC INDUSTRY Co., Ltd. as the general agent of Yi Der Enterprise Co., Ltd.

Since the beginning of 2005, in view of the uneven quality of the lubricant market, in order to enable consumers to use the quality comparable to or even better than that of major international brands, and to obtain them at the most reasonable price, it was entrusted to pass rigorous international quality control EUROILTEC, which is certified and has rich experience in foundry international brands, began to produce CASOKU.

Relying on the technical formula cooperation with major international additive manufacturers: LUBIRZOL, INFINEUM, AFTON... etc., we have produced an excellent market reputation. , Let CASOKU take it to the next level. Since 2012, the quality of CASOKU has not only been recognized by the military, it has begun to supply the military with battle armors, battle ships, vehicles, etc., and has also been designated for use by public power plants, public wheel ships, postal services, police consumption, environmental protection official vehicles, etc.! The number of private maintenance factories is even more numerous.

In 2015, EUROILTEC, a commissioned factory of CASOKU, won TAF ISO/IEC17025 certification and became a member of ILAC. Its inspection report has been approved by 74 countries around the world, which is a more rigorous quality control for CASOKU.

For more than ten years, CASOKU has continued to improve and grow. Through dozens of instruments and TAF certified precision and rigorous operation of EUROILTEC, it will become a new bright spot and indicator of the lubricant market.

CASOKU is equipped with the International Laboratory No. 44 (2013), which is officially certified by British Petroleum bp. It has more than 31 inspection items and various types of exclusive experimental equipment, and can obtain scientific data of scientific lubricants in a short time. In accordance with the ISO9001 international guarantee operation mode and TAF lubricant laboratory operation specifications, a series of strict controls and checks are carried out from raw materials to costs in all oil production processes, and the quality is absolutely guaranteed.

SGS Taiwan designated inspection cooperation laboratory

BP inspection qualified inspection room

| 1.Color | ASTM D1500 |

| 2.Specific Gravity | ASTM D4052 |

| 3.API Gravity | ASTM D4052 |

| 4.Density 15°C,g/ml | ASTM D4052 |

| 5.Water Content,vol% | ASTM D95 |

| 6.pH Value | pH Meter |

| 7.Kinematic Viscosity,cSt,40°C,100°C | ASTM D445 |

| 8.Viscosity Index,VI | ASTM D2270 |

| 9.Copper Strip test | ASTM D130 |

| 10.Sulfate Ash,wt% | ASTM D874 |

| 11.Total Acid Number,mg KOH/g | ASTM D664A |

| 12.Total Base Number,mg KOH/g | ASTM D2896B |

| 13.Flash Point,COC,°C | ASTM D92 |

| 14.Fire Point,°C | ASTM D92 |

| 15.Pour Point,°C | ASTM D97 |

| 16.Elements Analysis,ppmw | ASTM D4951/D5185 |

| 17.Foaming Characteristics,ml | ASTM D892 |

| 18.Emulsion Test | ASTM D1401 |

| 19.HTHS,106S-1,mPa·s,150°C | ASTM D5481 |

| 20.CCS,mPa·s | ASTM D5293 |

| 21.Water Content,ppmw | ASTM D6304A/C |

| 22.Particle Counts | NAS 1638,ISO 4406 |

| 23.Evaporation Loss,Noack Method,wt% | ASTM D5800B |

| 24.RPVOT,min. | ASTM D2272 |

| 25.CarobnResidue,Rams.,wt% | ASTM D524 |

| 26.Ash,wt% | ASTM D482 |

| 27.Rust Preventing Characteristics | ASTM D665 |

| 28.Elements Analysis,ppmw | ASTM D6481 |

| 29.Thermal Stability,CM,AN change | ASTM D6203 & D664A |

| 30.Salt Spray Testing | ASTM B117 |

| 31.Precipitation Number,ml | ASTM D91 |

| 32.n·Pentane Insoluble,wt% | ASTM D893A |

| 33.Toluene Insoluble,wt% | ASTM D893A |

| 34.Fat Content,wt% | ASTM E168 |

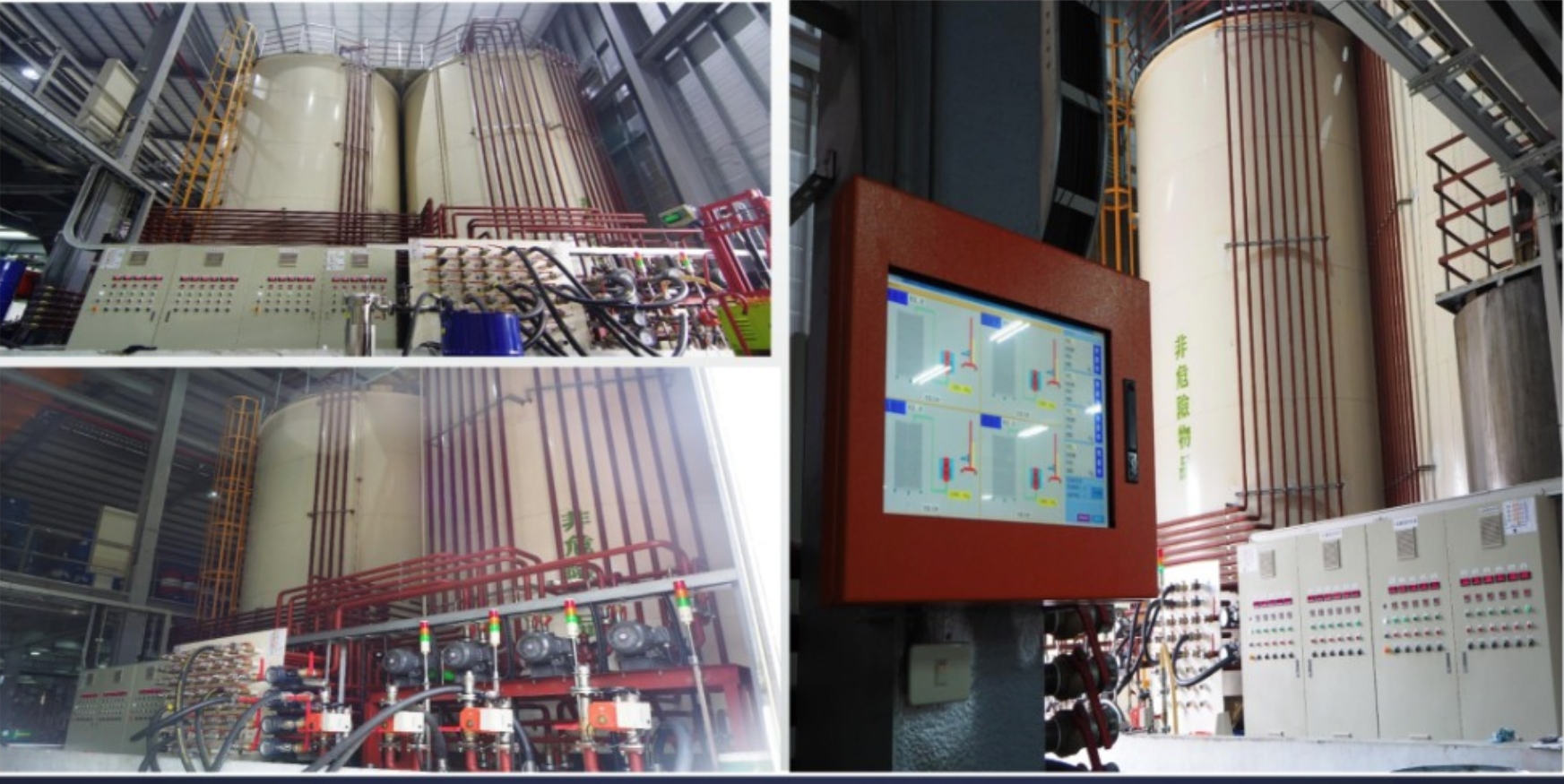

Automatic production line -1

Automatic production line -2

Automatic production line -3

Automatic filler

Automatic packing machine

Pallet wrapping packing machine